What kind of solution do you need?

Engine compartment

Our foams fulfil many essential functions in engine compartments, ranging from air and water sealing and sound isolation in the engine bay to acoustic absorption in the engine itself. We offer durable heat-resistant and fluid-resistant materials for engines, cables and wiring. Our foams are lightweight, helping to improve fuel efficiency and reduce harmful emissions. They are also designed for easy assembly and can be provided in customised designs to make life easier for manufacturers and installers.

ENGINE BAY

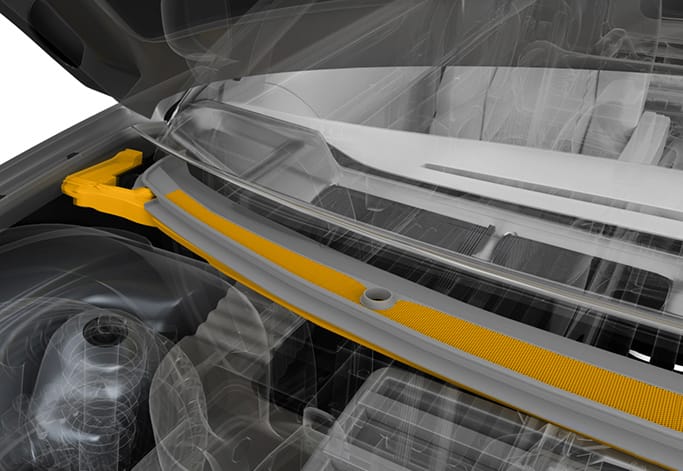

Bonnet lateral seals

Requirements

- Sound isolation and water sealing between bonnet and engine compartment

- Customised design

Our products

Cowl grille silencer

Requirements

- Engine bay noise reduction

- Low weight

- Easy assembly

- Fluid resistance

Our products

Air intake silencer

Requirements

- Sound absorption for engine air intakes

- Easy assembly

- Durability

Our products

Cowl top seal

Requirements

- Water sealing

- Good weatherability

Our products

ENGINE

Engine beauty cover

Requirements

- Low weight

- Acoustic absorption

- Heat and fluid resistance

Our products

Under engine

Requirements

- Low weight

- Self supporting

- Good processability

Our products

Diesel injection ramp silencer

Requirements

- Engine encapsulation (acoustic)

- Low weight

- Customised design

- High heat and fluid resistance

Our products

PCR Seal

Requirements

- Common rail diesel system sealing

- Fluid and heat resistance

Our products

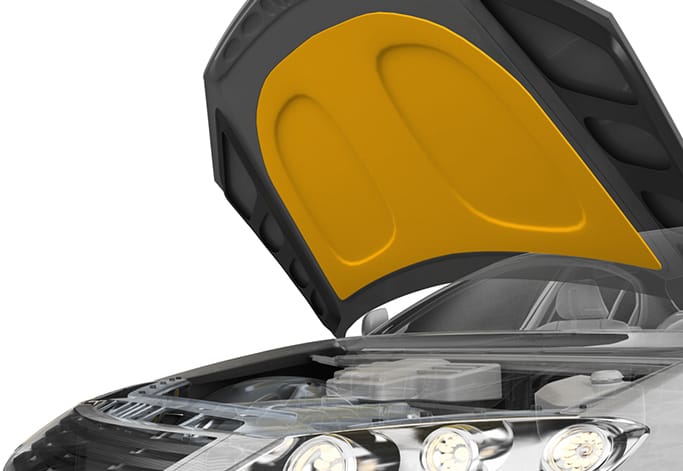

UNDER THE BONNET

Hood liner

Requirements

- Acoustic absorption

- Low weight

- Self supporting

- Good processability