Why choose Recticel Flexible Foams?

Our service model: end-to-end acoustic support for your projects

The world of industrial equipment is evolving towards quieter machines which help to protect people and the surrounding environment. As well as improving living standards, the latest silencing solutions help ensure that machinery meets, or ideally exceeds, applicable regulations.

Recticel offers a range of Acoustic Engineering Services to help resolve every thermal-acoustic challenge relating to your industrial equipment and facilities. Whether you want to improve a machine’s acoustic performance or optimise materials and space, we work with you to deliver the results you want in the most time- and cost-efficient way possible. Our extensive in-house capabilities enable quick measurement of materials and database cataloguing. Advanced research facilities, such as our Acoustic Competence Centres in Wetteren (Belgium) and Deer Park (New York), are located next to our manufacturing plants, eliminating the need for third-party labs and saving you time and money.

Advanced expertise, tools and modelling

Our highly developed product portfolio forms the basis of our materials toolbox, which we use to design concepts for specific applications such as industrial equipment inlets and outlets. Our materials cover the three main acoustic functions: noise absorption, transmission loss and vibration damping. For absorption and transmission loss applications, our materials are supported by internal measurement using reverberation room, alpha cabin and impedance tube technologies.

Modelling is a vital step in the development process. We can simulate the acoustic behaviour of the selected combination of materials, and thus optimise their performance. We also offer industrial room acoustic modelling to estimate the effect of solutions in situ and reduce noise in industrial equipment or at specific locations, e.g. workstations.

|

Do you have a project to discuss? Just get in touch, we are here to assist you!

|

A 3-step approach to refine your project

To determine what needs to be designed (or redesigned) in your equipment, we begin with reference measurements, carried out by you or by us, at your facilities or in our lab. This enables us to locate critical areas for development and make initial recommendations.

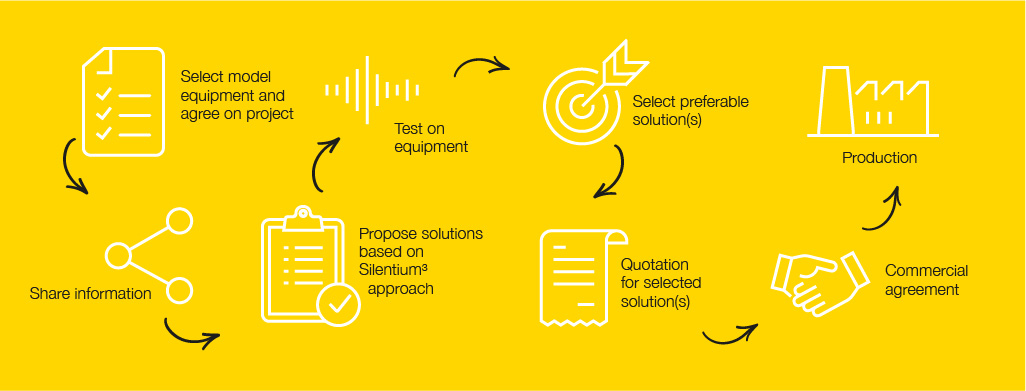

All our recommendations are based on our proven Silentium³ approach, consisting of three steps undertaken by acoustic engineers in cooperation with you. To complete these steps, we share more detailed information, such as 3D model drawings, airflow analysis and the specific noise signature of the equipment. Based on this information, we design a range of solutions.

After the initial analysis and recommendations, you decide whether to enter into an engineering/development project with us. Next, we define the scope of the project together. This includes selecting the proposals you would like us to prototype and test.

Download the Silentium³ brochure

Comprehensive testing capabilities

The solutions are tested at your facility or in our labs. On request, we can carry out detailed measurements at your site using sonometers, intensity probes or other equipment, depending on the applicable test standards. We can also measure your equipment, in full or in part, in a Recticel hemi-anechoic room, reverberant room, coupled room or alpha cabin. After thorough testing, we select the best solution for production.

|

Hemi anechoic chamber |

Coupled room |

Reverberant room |

Testing overview

| Industry acoustiscs | Labo acoustics | Labo physical properties |

|

|

|

Reporting and delivery

We keep you informed with regular reporting during and at the end of the project. Reports include the measurements and recommendations made, allowing detailed tracking of progress, results and conclusions.

When both parties are satisfied with the results, we then discuss the terms of our ongoing partnership. This may mean defining the terms of a commercial collaboration in which we supply you with the proposed parts, materials and solution. Alternatively, you may wish to continue working with us as your expert adviser on acoustic issues and measures. In any collaboration, you can rely on a clear agreement backed by regular communication and in-built flexibility to meet your needs as they evolve.

Want to talk about your project?

Please fill out the form below and we will get in touch to discuss your project in detail!

We care about your privacy. That's why we will only use your data to reply to your enquiry. Find out more in our privacy notice. At any moment, you can access, modify or have erased your personal data by sending a request to privacy.flexiblefoams@recticel.com.

* indicates a required field