Why choose Recticel Flexible Foams?

KAPUA® foam – made with climate-friendly innovation

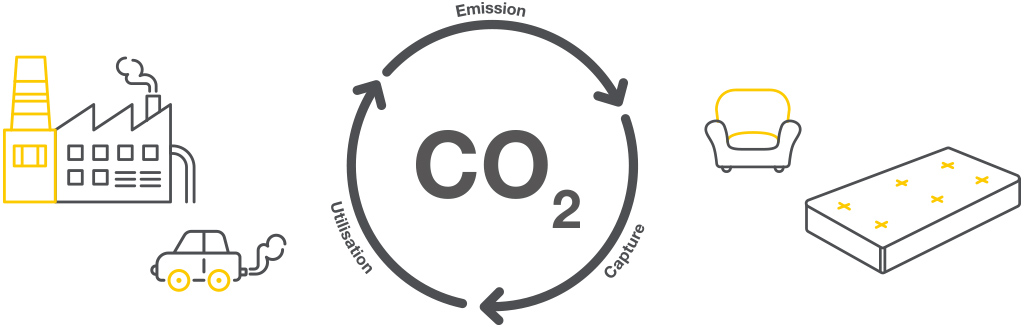

KAPUA® mattress foam is the first of our products to bear our new ‘made with climate-friendly innovation’ label, showing that it has been developed using the most advanced technologies to minimise environmental impact. When manufacturing this foam, a minimum of one-seventh of oil content is replaced by CO2 based chemicals. This helps to protect the environment by saving precious fossil resources and by removing harmful CO2 emissions from the atmosphere.

How does CO2 affect climate change?

CO2 is one of several greenhouse gases with the ability to trap heat in the atmosphere. In the right proportions, these gases act like a blanket surrounding the earth. Without them, the average temperature would be well below freezing and life on our planet would be impossible. Unfortunately, when the concentration of these gases increases beyond a balanced level, the insulating ‘blanket’ becomes too thick and temperatures rise as less heat escapes into space. This greenhouse effect is the cause of global warming and, consequently, climate change.

Although there are several heat-trapping gases, CO2 is the main culprit when it comes to climate change and puts us at the greatest risk of irreversible changes if it continues to accumulate in the atmosphere at the current rate. The earth is suffering from a carbon overload, which, since the Industrial Revolution, has mainly been caused by human activities such as fossil fuel use, deforestation, intensive livestock farming, use of synthetic fertilizers and industrial processes.

Ice core records carried out at the Antarctic leave no doubt that atmospheric CO2 levels today are higher than at any time over the last 800,000 years. They have increased by about 90% since 1970, and emissions from fossil fuel combustion and industrial processes contributed about 78% of the total greenhouse gas emissions increase between 1970 and 2011.

Tackling the carbon challenge

In December 2015, the Paris Agreement was signed, a global climate change agreement with the United Nations Framework Convention on Climate Change (UNFCCC). It laid the groundwork for a low-carbon future with its objective of limiting the global temperature increase to max.2°C by 2100 compared to pre-industrial levels. The United Nations has recommended a 50% decrease in CO2 emissions by 2050 compared to 1990 levels, and a 100% reduction by 2100.

In this video leading entrepreneurs and thinkers discuss why we need to reimagine our relationship with Carbon.

(source: UNGlobalCompact & VOLANS)

Industrial manufacturers, organisations and many individuals are pursuing carbon neutral status, which is most commonly achieved by using renewable energy or through carbon offsetting (e.g. by planting trees, funding ‘carbon projects’ that lead to the reduction of future greenhouse gas emissions).

How does KAPUA® help?

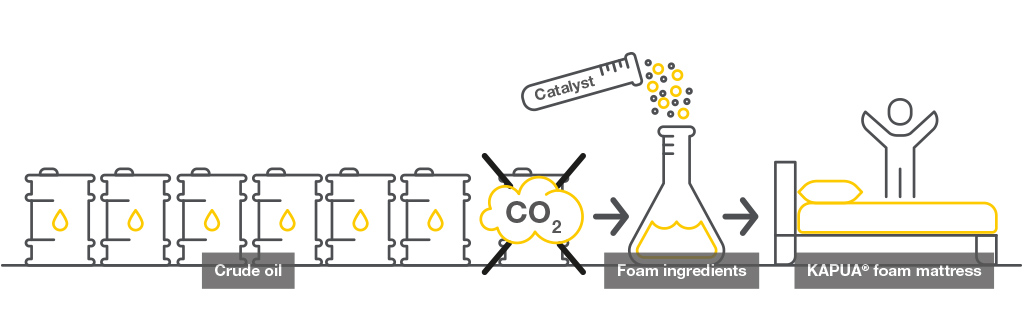

Polyurethane foam is made from two ingredients that are traditionally derived from crude oil: di‐isocyanates and polyols. When these ingredients are mixed, they react and foam.

Crude oil is far from ideal as a raw material. Supplies are depleting rapidly, and extraction and processing use huge amounts of energy. They also generate CO2 emissions on a massive scale. CO2 , on the other hand, is a by-product of industry, transport and other sectors, and is available in immense quantities.

Thanks to a new technology, developed by our partners like Covestro, this greenhouse gas can now be captured and used to produce a polyol. The new raw material doesn’t just save precious fossil resources in production processes: it also helps to remove CO2 from the atmosphere.

Using CO2 instead of oil in this process is not as simple as it sounds. The gas is extremely inert and does not combine quickly with other chemicals. To harness it and use it efficiently, scientists had to discover a new ingredient and a new process. The breakthrough came when Covestro scientists discovered the right catalyst to produce polyols using CO2 as a carbon source.

Thanks to this new technology, CO2 can be used as a partial substitute for oil when creating PU flexible foams like KAPUA® mattress foam. When manufacturing KAPUA® foam, a minimum of one-seventh of oil content is replaced by CO2 based chemicals.

KAPUA®: the perfect recipe for a good night’s sleep

A mattress made with KAPUA® foam is thoroughly tested for hardness, density and durability to ensure premium comfort over a long lifetime. It meets the strictest emissions requirements and is certified for safety by OEKO-TEX® and CertiPUR®.

Best of all, it bears the Recticel ‘made with climate-friendly innovation’ label, showing that it has been developed using the most advanced technologies to minimise environmental impact.

Two versions are currently available: KAPUA® M130 for mattress cores and KAPUA® S90 for mattress top layers.

For more information and samples, send an email to kapua@recticel.com or contact your Recticel representative.